70,000 items, approximately 100 locations and 175 years of service. We have what you need.

Find Out More

Ryerson supplies the widest variety of stainless steel products in North America. We use various processing and fabricating techniques to cut and shape our material to exact dimensions and forms. Our wide variety of stainless steel sheet and stainless steel plate can be cut-to-length or cut-to-sketch to meet your needs. As a full-line stainless steel supplier, we inventory a deep selection of stainless steel bar stock including stainless steel round bar, stainless steel flat bar, stainless steel square bar and stainless steel rectangular bar. We also cut stainless steel bar, stainless steel tubing and stainless steel structural shapes (including stainless steel angle, stainless steel channel and stainless steel beams) to almost any size to support your manufacturing processes.

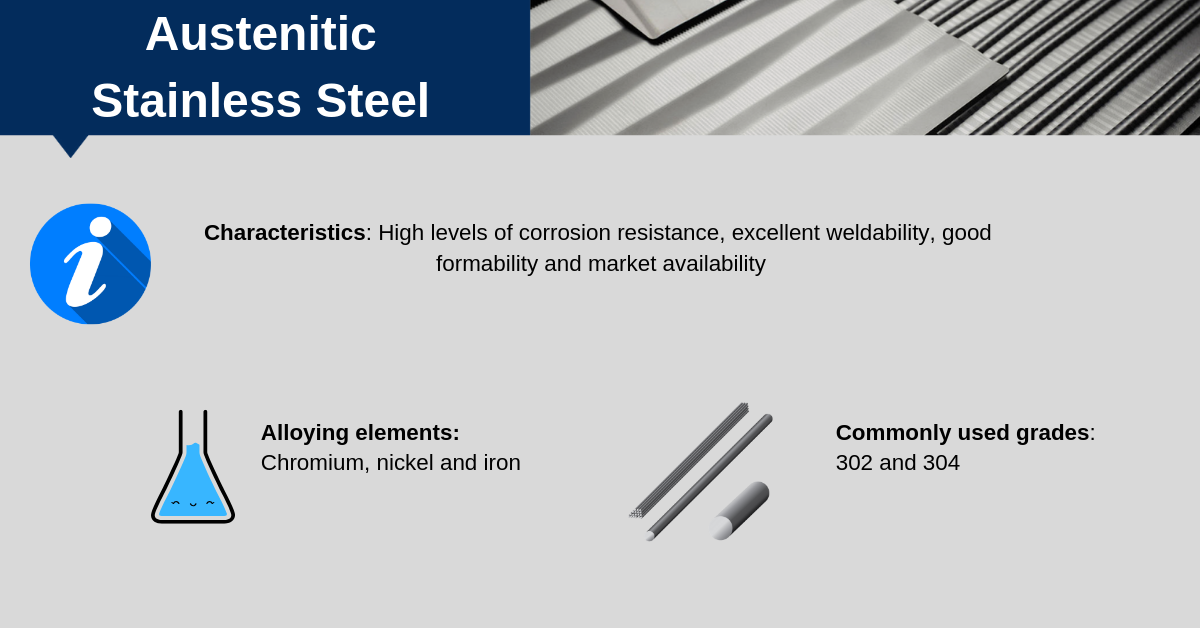

All stainless steels are iron-based alloys that contain at least 10.5% chromium. This helps with stainless steel grades being corrosion resistant; an important factor due in large part to the varying types of environments in which the end products are used.

Beyond chromium, the rest of the makeup of each stainless steel grade is defined by various alloying elements, which control the microstructure of the alloy.

Today there are roughly 200 different stainless steel grades—all of which fall under one of five families of stainless steel:

| Family | Weldability | Ductility | High Temp Resistance | Common Grades | Corrosion Resistance |

| Austenitic | High | High | High | 304, 310, 316 | High |

|---|---|---|---|---|---|

| Ferritic | Low | Medium | High | 430 | Medium |

| Martensitic | Low | Low | Low | 410, 420 | Medium |

| Duplex | High | Medium | Low | 2205 | |

| Precipitation Hardening | Low | Medium | Low | 630 |

Austenitic represents roughly 50% of the stainless steel used today. In fact, two of the most widely used stainless steel grades fall within this family: 304 stainless steel and 316 stainless steel. Both contain high levels of chromium and nickel.

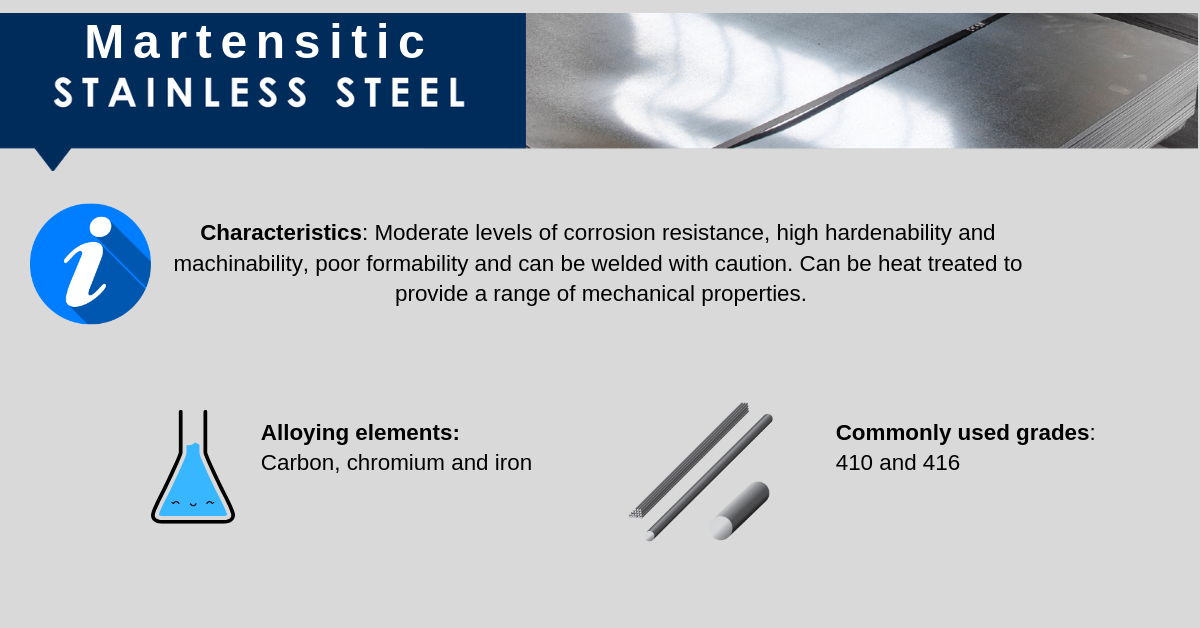

Martensitic stainless steel grades contain moderate levels of corrosion resistance, high hardenability and machinability, poor formability and can be welded with caution. They can be heat-treated to provide a range of mechanical properties.

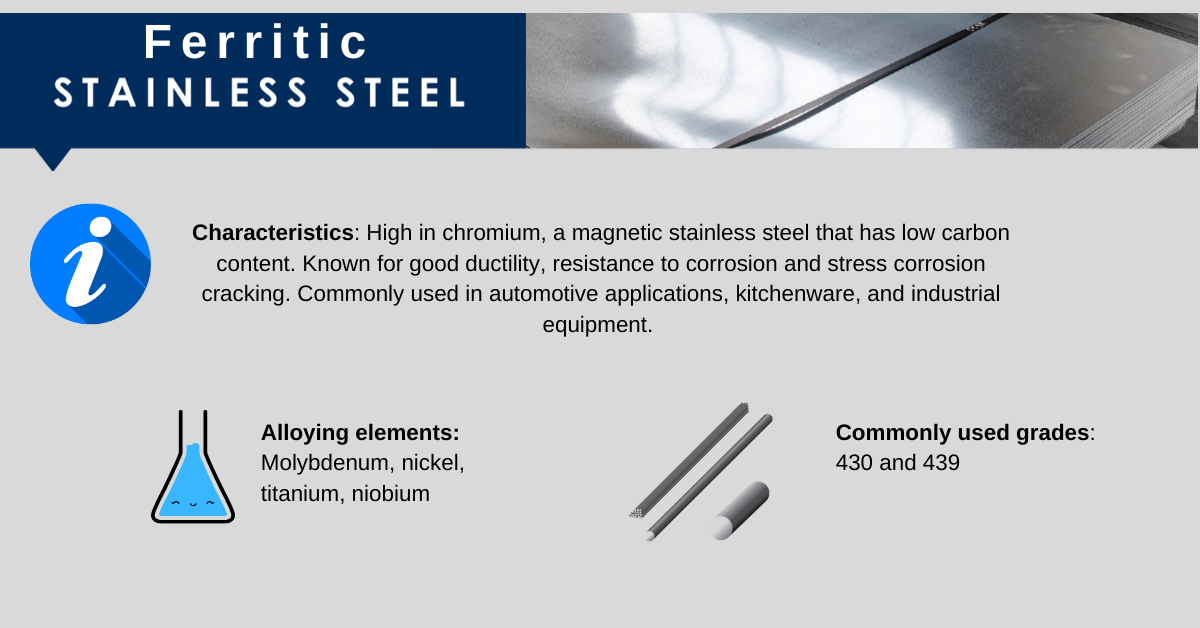

Ferritic stainless steel grades are high in chromium, magnetic stainless steels that have low carbon content. Known for good ductility, resistance to corrosion and stress corrosion cracking. Commonly used in automotive applications, kitchenware, and industrial equipment.

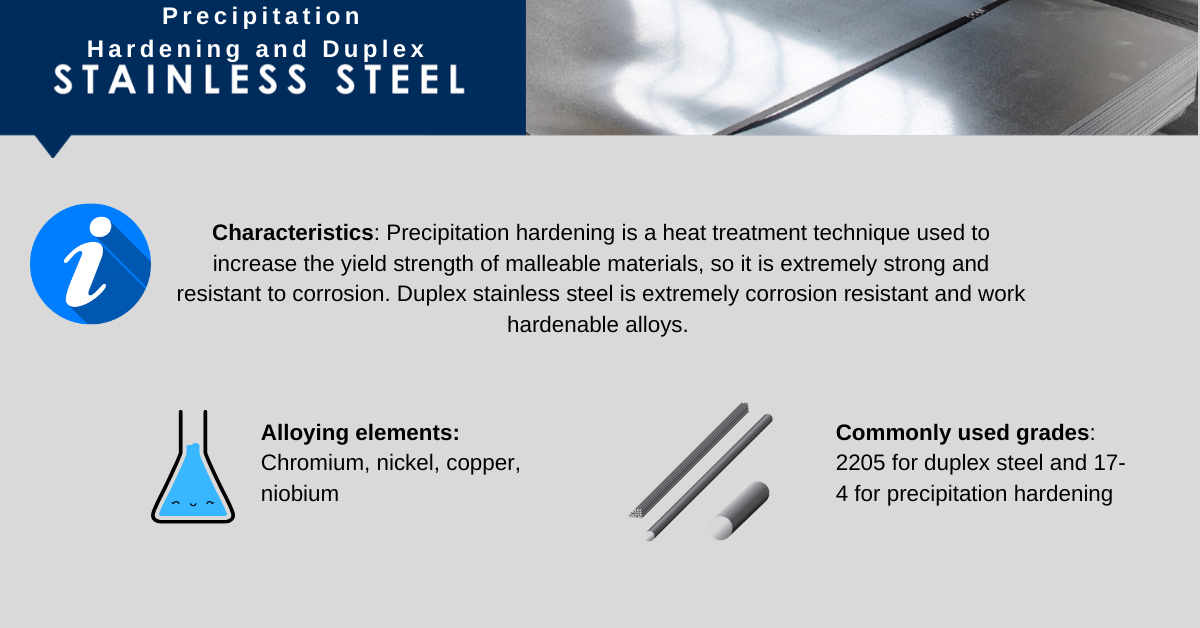

Precipitation hardening is a heat treatment technique used to increase the yield strength of malleable materials, so it is extremely strong and resistant to corrosion. Duplex stainless steel is extremely corrosion resistant and work hardenable alloys.

304 stainless steel is the most widely used grade, most notably present in industrial applications and kitchen equipment. It is a highly heat-resistant stainless steel grade and offers good corrosion resistance to many chemical corrodents, as well as industrial atmospheres. With good formability, 304 stainless steel can be readily welded by all common methods.

304L is an extra low carbon variation that avoids harmful carbide precipitation due to welding. This variation offers the same corrosion resistance as 304 stainless steel, but with slightly lower mechanical properties.

When it comes to 316 stainless steel, you can expect better corrosion and pitting resistance to chlorides than 304 stainless steel and higher levels of strength at elevated temperatures. This is due in part to the addition of molybdenum. This is what makes it an ideal stainless steel grade for such applications as pumps, valves, textile and chemical equipment, pulp & paper and marine applications.

316L is the extra-low carbon version of 316 stainless steel that helps avoid carbide precipitation due to welding.

Now to the question of 304 vs. 316 stainless steel; while both are good for corrosion resistance, strength, welding, and heat resistance, 316 stainless steel gets the slight edge in all these categories due to variation in alloying elements.

Did you know that the price of stainless steel grades 304 and 316 can fluctuate based on the ebb and flow of the raw material cost? To help offset these fluctuations, surcharges are added to the base price, typically per pound and varied by the mill.

From precision cutting to punching, bending and welding, we have the capabilities to transform metal into what you need.

We have the ability to produce engineered-to-order parts that meet your exact specifications. Our facilities have diverse capabilities, providing quick service and specialized processing.